Rail Services Engineered for Performance

Field-tested Innovation

Evorail delivers precision engineering and field-tested innovation across every layer of locomotive operations. From full rebuilds to intelligent control upgrades, our services are designed to extend asset life, reduce downtime, and meet the evolving demands of modern rail networks.

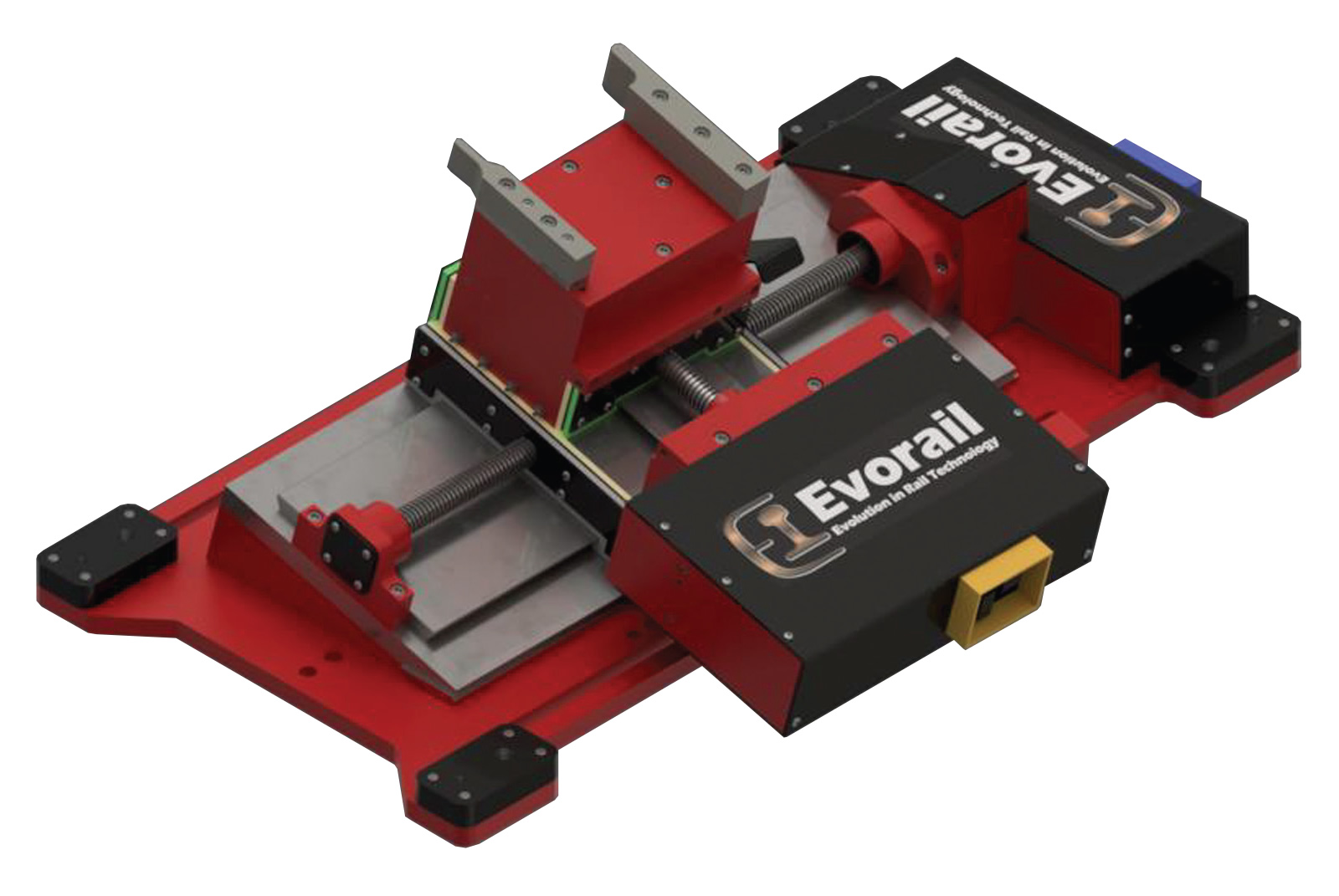

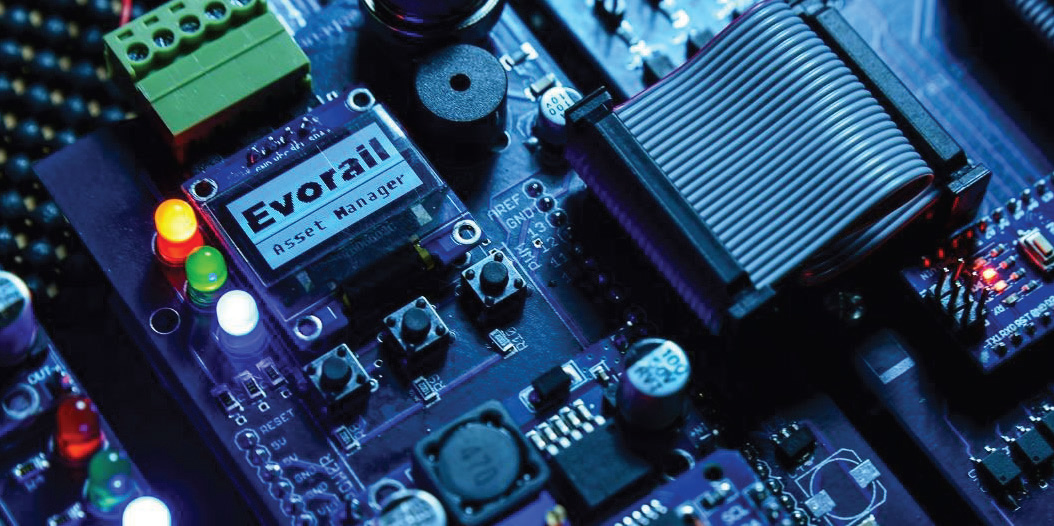

End-to-end locomotive rebuilds and manufacturing – Advanced control system upgrades for traction and diagnostics – On-site wheel profiling to eliminate transport delays –End-to-end locomotive rebuilds and manufacturing – Advanced control system upgrades for traction and diagnostics – On-site wheel profiling to eliminate transport delays –

Strategic asset management for fleet reliability • GPS speedometer installations for enhanced safety • Integrated brake testing systems for vacuum and air wagons • EN50155-compliant on-board camera systems with live monitoring • Strategic asset management for fleet reliability • GPS speedometer installations for enhanced safety • Integrated brake testing systems for vacuum and air wagons • EN50155-compliant on-board camera systems with live monitoring •